The Hull Shell, Sheer to Keel, is complete. 1300 hours for 1100kg of planking plus bulkheads (not yet bonded). Almost 1kg per hour to this stage although there is still a few hours of dressing to go.

Dressing involves removing a minimum thickness of the proud plank edges using a small block plane with 25 degree blade bevel .

After dressing the planking is given a light 40G orbital sanding. The new 700W Makita Sander comes standard with a built in Samurai Warrior who endeavours to throw one off the boat particularly when working high up near the keel and hanging on by ones teeth.

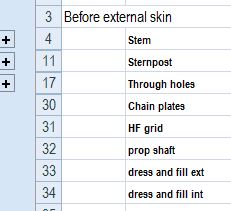

Before laminating the 120kg of epoxy E-glass Outer Skin there are a few tasks yet to complete. And then I will need a few days with ambient temperatures less than 30 degrees C. I’m already seeing 42 C at one meter off the floor and 46C higher up nearer the roof, so it may be March 2018 before the outer skin laminates go on. There is plenty of fill in work to keep me busy until then including the Rudder and False Keel.

Very Good ! Good to see the boat taking shape ! Merry Christmas ! Fair winds!

Em sáb, 23 de dez de 2017 às 11:37, THE PINGO PROJECT escreveu:

> thepingoproject posted: ” The Hull Shell, Sheer to Keel, is complete. 1300 > hours for 1100kg of planking plus bulkheads (not yet bonded). Almost 1kg > per hour to this stage although there is still a few hours of dressing to > go. Dressing involves removing a minimum thickness o” >

LikeLike